how manufacturing high pressure laminates sheet

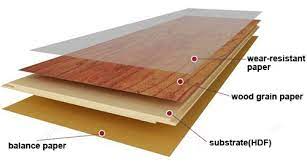

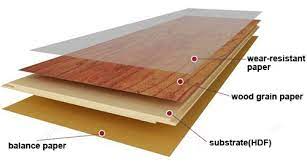

High pressure laminate sheets are a type of decorative surfacing material that is widely used in interior design and construction. They are made by combining multiple layers of kraft paper or decorative paper with melamine resins and then compressing them under high pressure and temperature.

The process of manufacturing high pressure laminate sheets involves the following steps:

- Paper preparation: The base papers used in the manufacture of high pressure laminate sheets are usually made from kraft paper or decorative paper. These papers are impregnated with melamine resin, which provides the material with its characteristic hardness and durability.

- Layering: Several layers of impregnated paper are laid out in a stack, with each layer oriented in a different direction. This cross-hatching pattern ensures that the resulting laminate sheet is strong and stable.

- Pressing: The layered stack of paper is then placed inside a large press, which applies both heat and pressure to the material. The pressure can range from 500 to 1400 psi, while the temperature can reach up to 300°F. The exact conditions used will depend on the specific type of laminate being manufactured.

- Trimming and finishing: After the laminate has been compressed, it is trimmed to size and the edges are finished with a router or other cutting tool. The finished product can then be further processed to add texture, color, or other features as desired.

Overall, the manufacturing process for high pressure laminate sheets is a complex and precise one, requiring careful attention to detail and adherence to strict quality standards to ensure that the resulting material is strong, durable, and aesthetically pleasing.